Guide to Understanding HVAC Control Boards and Finding the Right PCB Manufacturers for Your Project

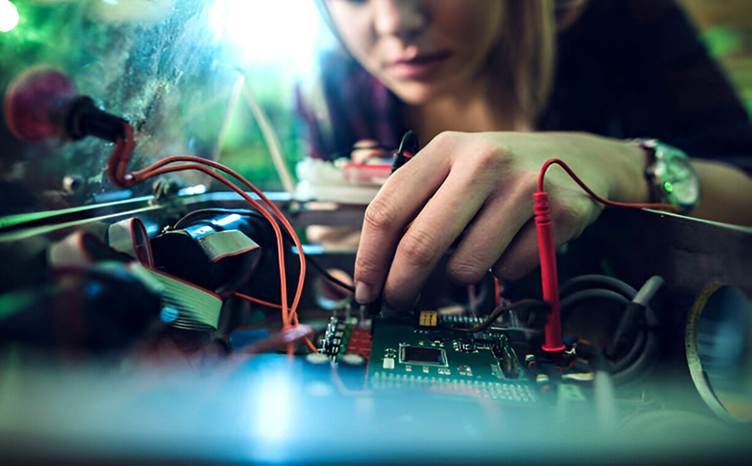

Heating, ventilation, and air conditioning (HVAC) systems have become an essential part of modern homes, offices, and industrial buildings. At the heart of every HVAC system is a small but crucial component—the control board. This electronic circuit board is responsible for managing and coordinating the operation of the entire HVAC unit.

In this guide, we’ll break down how HVAC control boards work, what makes them critical, and why working with trusted PCB manufacturers in the USA for your project can make all the difference in reliability and performance.

What Is an HVAC Control Board?

An HVAC control board is the central control system that governs the functions of your furnace, air conditioner, heat pump, or full HVAC unit. Often referred to as the “brain” of the system, this printed circuit board (PCB) manages operations such as:

- Fan control

- Ignition timing

- Safety checks

- Thermostat communication

- Relay switching

It collects signals from sensors and the thermostat, processes the data, and then sends the right commands to various components like the blower motor, gas valve, or compressor. Without a functioning control board, your HVAC system won’t respond properly—or may not operate at all.

Key Components of an HVAC Control Board

To understand how HVAC control boards work, it’s important to know the major components typically found on the board:

- Microcontroller: Acts as the main processor and makes decisions based on incoming signals.

- Relays and switches: Turn different parts of the system on and off.

- Capacitors and resistors: Regulate voltage and protect sensitive circuits.

- Connectors and terminals: Provide input/output paths to thermostats, sensors, and mechanical components.

- Diagnostic LEDs: Help identify issues when a system malfunctions.

Many modern HVAC control boards also include surge protection, memory for fault codes, and advanced features for energy efficiency.

How the Control Board Works in Real-Time

Here’s a simplified look at what happens when you adjust your thermostat:

- Signal Received: The thermostat sends a signal to the control board (e.g., request for cooling).

- Safety Checks: The board ensures conditions are safe—checking sensors for flame detection, pressure, and more.

- Activate Components: If safe, it sends commands to activate the compressor and blower.

- Monitoring: While running, the board continually monitors temperature, airflow, and sensor data.

- Shut Down: When the desired temperature is reached or a fault is detected, the board deactivates the system.

This level of coordination is only possible through careful design and reliable circuit board manufacturing.

Why HVAC Control Board Quality Matters

HVAC systems are expected to operate in challenging environments, often exposed to temperature swings, moisture, and electrical surges. That’s why the quality of the control board matters so much. Poorly made PCBs can result in:

- Shortened HVAC lifespan

- Frequent repairs and replacements

- Safety hazards like short circuits or overheating

- Energy inefficiency

To avoid these issues, you need a high-quality HVAC control board produced by a dependable PCB manufacturer.

Choosing PCB Manufacturers in the USA for Your Project

If you’re developing or upgrading HVAC systems, selecting the right PCB manufacturers in the USA for your project is essential. Domestic manufacturers offer several advantages:

1. Quality Assurance and Certifications

Many U.S.-based PCB manufacturers comply with strict industry standards such as IPC-A-600, ISO 9001, and UL certifications. These ensure consistency, safety, and top-quality production.

2. Faster Turnaround Times

Working with domestic PCB manufacturers reduces shipping delays and speeds up prototyping and revisions. For HVAC system developers, this means quicker time-to-market and easier handling of urgent modifications.

3. Better Communication

Being in the same time zone allows for real-time communication, which is especially helpful when dealing with custom board designs, engineering changes, or troubleshooting.

4. IP Protection

For companies with proprietary HVAC control designs, partnering with a U.S.-based manufacturer offers better protection for intellectual property and design files.

What to Look for in a PCB Manufacturer for HVAC Projects

Not all PCB manufacturers are equally equipped to handle HVAC applications. When evaluating potential partners, look for these features:

- Experience with high-power boards: HVAC systems often operate on high current loads, so experience in handling heat dissipation and power electronics is vital.

- Environmental testing capabilities: Ensure the manufacturer can provide boards that are tested for moisture, vibration, and temperature variations.

- Flexible order volumes: Whether you need a prototype or a production run, choose a manufacturer who can scale with your project.

Some reliable PCB manufacturers in the USA specialize in HVAC, appliance, and industrial control systems. Their knowledge of application-specific requirements gives you an advantage in designing control boards that last.

Also Read: What Industries Can Benefit Most from Implementing Biometric AML Checks?

Final Thoughts

Understanding the role of HVAC control boards helps highlight how critical they are to the smooth operation of heating and cooling systems. From managing thermostat signals to controlling fans and safety circuits, these boards are complex, high-reliability components.

To ensure your control board performs well in harsh conditions, it’s crucial to partner with reputable PCB manufacturers in the USA for your project. The right partner can support your design needs, maintain high quality, and deliver boards on time and within budget.

Whether you’re building an HVAC product line or retrofitting an older system, start with a well-designed PCB—manufactured with precision, reliability, and care.